- Home Page

- Company Profile

-

Our Products

- Programmable Logic Controller (PLC)

- Human Machine Interface HMI - MMI

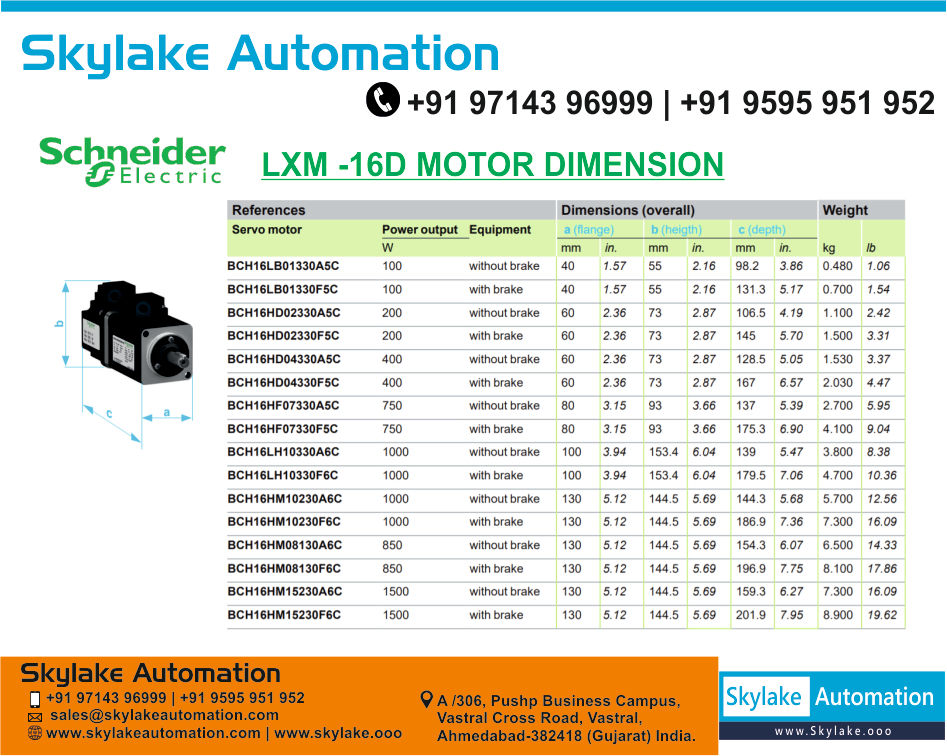

- Servo System

- Lexium 16 Servo Motor Bch16ha07330a5c - 750 Watt

- Lexium 16 Servo Motor Bch16hm10230a6c - 1000 Watt

- Panasonic Servo System

- Lexium 16 Servo Motor Bch16hd04330a5c - 400 Watt

- Lexium 16d Servo Drive Lxm16du10m2x - 1000 Watt

- Lexium 16d Servo Lxm16du07m2x - 750 Watt

- Lexium 16d Servo Drive Lxm16du04m2x - 400 Watt

- Drives and VFD

- Atv-310 Schneider Vfd Atv310hu22n4e - 2.2kw, 3 Hp

- Schneider Drive

- Atv-310 Schneider Atv310hd11n4e, 11kw , 15hp

- Atv-310 Schneider Atv310hu75n4e Vfd, 7.5kw, 10 Hp

- Atv-310 Schneider Atv310hu55n4e Vfd, 5.5kw, 7.5hp

- Atv-310 Schneider Vfd Atv310hu15n4e - 1.5kw, 2 Hp

- Atv310 Schneider Vfd - Atv310h075n4e-0.75kw- 1 Hp

- Atv-12 Schneider Vfd Atv12h018m2 -0.18kw,0.25hp

- Atv-12 Schneider Vfd - Atv12h075m2 , 0.75kw , 1 Hp

- Atv-12 Schneider Vfd Atv12hu15m2 - 1.5kw, 2 Hp

- Atv-12 Schneider Vfd Atv12hu22m2 - 2.2kw

- Control Panel

- Programming and Interface Cable

- Proxy Sensor

- Process Control Instruments

- Automation Service

- PLC System

- Panasonic PLC

- SMPS

- MeanWell SMPS Two

- Meanwell SMPS

- LRS-50-24 Meanwell Power Supply SMPS -2

- EDR-120-24 Meanwell SMPS

- LRS-150-24 Meanwell SMPS

- LRS-75-24 Meanwell SMPS

- LRS-100-24 Meanwell SMPS

- LRS-200-24 Meanwell SMPS

- LRS-350-24 Meanwell SMPS

- SE-450-24 Meanwell SMPS

- SE-450-36 Meanwell SMPS

- SE-600-24 Meanwell SMPS

- SE-600-27 Meanwell SMPS

- SE-1000-24 Meanwell SMPS

- SE-1500-24 Meanwell SMPS

- LRS-350-36 Meanwell SMPS

- RS-25-5 Meanwell SMPS

- AC Drive

- Industrial PCS - SCHNEIDER Easy Harmony Panel iPC

- HMI Touch Panel

- Colour Mark Sensor

- Fiber Optic Sensor

- Panasonic Logic Controller

- Servo Driver

- HMI Control Panel

- Schneider Switch Mode Power Supply - SMPS

- Label Gap Sensors

- Baumer Non-transparent Label Gap Sensor

- Di-Soric Optical Label Sensor OGUTI 00550 FG3K-TSSL

- U1HJ001 Fork Transparent Lable Gap Sensor Wenglor

- Telemecanique XUVE04M3KSNM8 non transparent label gap sensor

- Telemecanique transparent label gap sensor XUVU06M3KSNM8

- Baumer OL05.I-GP1B.7WN Non-Transparent Label Gap Sensor

- Mornsun SMPS

- Mornsun SMPS-LM50-22B12 50 Watt 4.2 Amp 12Vdc

- Mornsun SMPS-LM350-10B24 350 Watt 14.6 Amp 24Vdc

- Mornsun SMPS-LM35-22B24 35 Watt 1.5 Amp 24Vdc

- Mornsun SMPS-LM350-10B36 350 Watt 9.7 Amp 36Vdc

- Mornsun SMPS-LM75-22B12 75 Watt 6 Amp 12Vdc

- Mornsun SMPS-LM50-20B12 50 Watt 4.2 Amp 12Vdc

- Mornsun SMPS-LM200-12B12 150 Watt 17 Amp 12Vdc

- Mornsun SMPS-LM75-20B24 75 Watt 3.2 Amp 24Vdc

- Mornsun SMPS-LM75-20B12 75 Watt 6 Amp 12Vdc

- Mornsun SMPS-LM100-20B24 100 Watt 4.5 Amp 24Vdc

- Mornsun SMPS-LM100-20B12 100 Watt 8.5 Amp 12Vdc

- Mornsun SMPS-LM100-22B12 100 Watt 8.5 Amp 12Vdc

- Mornsun SMPS-LM150-20B12 150 Watt 12.5 Amp 12Vdc

- Mornsun SMPS-LM350-12B36 350 Watt 9.7 Amp 36Vdc

- Mornsun SMPS-LM350-10B12 350 Watt 29 Amp 12Vdc

- Mornsun SMPS-LM350-10B48 350 Watt 7.3 Amp 48Vdc

- Mornsun SMPS-LM350-12B24 350 Watt 14.6 Amp 24Vdc

- Mornsun SMPS-LM200-10B24 150 Watt 8.8 Amp 24Vdc

- Mornsun SMPS-LM200-12B24 200 Watt 8.8 Amp 24Vdc

- Mornsun SMPS-LM150-22B12 150 Watt 12.5 Amp 12Vdc

- Mornsun SMPS-LM350-12B12 350 Watt 29 Amp 12Vdc

- Mornsun SMPS-LM100-22B24 100 Watt 4.5 Amp 24Vdc

- Mornsun SMPS-LM200-10B12 150 Watt 17 Amp 12Vdc

- Mornsun SMPS-LM75-22B24 75 Watt 3.2 Amp 24Vdc

- Mornsun SMPS-LM35-20B24 35 Watt 1.5 Amp 24Vdc

- Mornsun SMPS-LM50-22B24 50 Watt 2.2 Amp 24Vdc

- Mornsun SMPS-LM50-20B24 50 Watt 2.2 Amp 24Vdc

- Mornsun SMPS-LM150-20B24 150 Watt 6.5 Amp 24Vdc

- Mornsun SMPS-LM150-22B24 150 Watt 6.5 Amp 24Vdc

- Panasonic Servo

- Schneider VFD AC Drive

- Delta Switch Mode Power Supply - SMPS

- Crompton Ac Drive

- Telemecanique Label Sensor

- Contact Us

Lexium 16d Servo Lxm16du07m2x - 750 Watt

15500 INR/Piece

Product Details:

- Humidity 10% to 90% RH (non-condensing)

- Input Current 5.2A

- Mounting Type Panel Mount

- Output Voltage 3-phase, 0 to input voltage

- Frequency 50/60 Hz

- Efficiency High Efficiency

- Rated Voltage 230V AC

- Click to View more

X

Lexium 16d Servo Lxm16du07m2x - 750 Watt Price And Quantity

- 1 Piece

- 15500 INR/Piece

- -20°C to 65°C

- Class I

- RS-485, CANopen, Modbus

- Vector Control / Pulse / Analog

- 750 Watt (0.75 kW)

- Built-in Dynamic Braking

- LED Status Indicators

- Natural Air Cooling (Fanless)

- Approx. 1.6 kg

- Lexium 16d Lxm16du07m2x

- Incremental Encoder / Absolute Encoder Support

Lexium 16d Servo Lxm16du07m2x - 750 Watt Product Specifications

- Motion Control for Precision Automation

- 230V AC

- 750 Watt

- New

- 10% to 90% RH (non-condensing)

- Servo Drive

- High Efficiency

- Standard Manufacturer Accessories

- 50/60 Hz

- 3-phase, 0 to input voltage

- 155 x 67 x 170 mm

- Servo drive

- Metal and Industrial Grade Plastic

- 200-240V AC

- Industrial Automation, CNC Machines, Robotics

- IP20

- Panel Mount

- Single / Three Phase

- 5.2A

- AC Powered

- 0C to 40C

- -20°C to 65°C

- Class I

- RS-485, CANopen, Modbus

- Vector Control / Pulse / Analog

- 750 Watt (0.75 kW)

- Built-in Dynamic Braking

- LED Status Indicators

- Natural Air Cooling (Fanless)

- Approx. 1.6 kg

- Lexium 16d Lxm16du07m2x

- Incremental Encoder / Absolute Encoder Support

Lexium 16d Servo Lxm16du07m2x - 750 Watt Trade Information

- Asia

- All India

Product Description

Lexium 16d Servo Lxm16du07m2x - 750 Watt

Nominal Speed : 3000 rpm

Nominal Torque : 2.39 Nm

Moment of Inertia : High8 Wire 2500 PPR Incremental Encoder 100 mm Flange size

Technical Specification

| Input Phase | 1 - Phase |

| Input Voltage | Single Phase |

| Torque | 2.39 NM |

| Speed Range | 3000 RPM |

| Model Name/Number | LXM16DU07M2X |

| Motor Type | AC Servo drive |

| Output Power | 750 Watt |

| Brand | Schneider |

Advanced Motion Control

Engineered for industrial automation, the Lexium 16d Servo Lxm16du07m2x delivers smooth and precise movement for applications such as CNC machines and robotic systems. Its vector control enables adaptable and accurate performance across diverse tasks, supporting both incremental and absolute encoders for maximum feedback flexibility.

Robust Connectivity and Safety

With integrated RS-485, CANopen, and Modbus communication interfaces, this servo drive ensures smooth data flow and adaptability to various industrial networks. Safety is enhanced by a built-in dynamic braking unit and IP20-rated enclosure, protecting against dust ingress and ensuring safe panel mounting.

Efficient and Reliable Operation

Operating on 200-240V AC with high efficiency, the Lxm16du07m2x minimizes power consumption while maintaining consistent output. Natural air cooling (fanless) and a robust build ensure long-term performance with minimal maintenance, making it ideal for demanding environments in India.

FAQ's of Lexium 16d Servo Lxm16du07m2x - 750 Watt:

Q: How do I install the Lexium 16d Lxm16du07m2x servo drive?

A: Mount the drive on a secure panel using the provided brackets, ensuring adequate space for airflow around the unit. Connect the power supply (200-240V AC), input signals, and communication interfaces such as RS-485, CANopen, or Modbus. Ensure wiring conforms to the indicated phase and voltage requirements.Q: What applications benefit most from using this servo drive?

A: The Lexium 16d Lxm16du07m2x is well-suited for industrial automation sectors, including CNC machinery, pick-and-place robotics, and other precision-driven systems where accurate, responsive motion control is essential.Q: When should I use the built-in dynamic braking function?

A: Utilize the built-in dynamic braking during high-speed deceleration or emergency stops. The dynamic braking feature dissipates excess energy safely, protecting both the drive and the connected machinery during abrupt stops.Q: Where can I integrate this servo drive within an existing automation system?

A: This servo drive is designed for flexible panel mounting and can be integrated into main control panels or existing automation cabinets. Its multiple communication interfaces allow easy network integration in most industrial setups.Q: What process should I follow to configure communication protocols?

A: Connect to the drive using the appropriate port (RS-485, CANopen, or Modbus) and follow the manufacturer's documentation to set parameters, address, and baud rate. Configuration can be done using the LED indicators and compatible programming tools.Q: How does natural air cooling (fanless design) benefit the user?

A: Natural air cooling eliminates the need for internal fans, reducing operating noise and the risk of fan-related failures. This design lowers maintenance demands while ensuring efficient thermal management in the specified temperature range.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free