- Home Page

- Company Profile

-

Our Products

- Programmable Logic Controller (PLC)

- Human Machine Interface HMI - MMI

- Servo System

- Lexium 16 Servo Motor Bch16ha07330a5c - 750 Watt

- Lexium 16 Servo Motor Bch16hm10230a6c - 1000 Watt

- Panasonic Servo System

- Lexium 16 Servo Motor Bch16hd04330a5c - 400 Watt

- Lexium 16d Servo Drive Lxm16du10m2x - 1000 Watt

- Lexium 16d Servo Lxm16du07m2x - 750 Watt

- Lexium 16d Servo Drive Lxm16du04m2x - 400 Watt

- Drives and VFD

- Atv-310 Schneider Vfd Atv310hu22n4e - 2.2kw, 3 Hp

- Schneider Drive

- Atv-310 Schneider Atv310hd11n4e, 11kw , 15hp

- Atv-310 Schneider Atv310hu75n4e Vfd, 7.5kw, 10 Hp

- Atv-310 Schneider Atv310hu55n4e Vfd, 5.5kw, 7.5hp

- Atv-310 Schneider Vfd Atv310hu15n4e - 1.5kw, 2 Hp

- Atv310 Schneider Vfd - Atv310h075n4e-0.75kw- 1 Hp

- Atv-12 Schneider Vfd Atv12h018m2 -0.18kw,0.25hp

- Atv-12 Schneider Vfd - Atv12h075m2 , 0.75kw , 1 Hp

- Atv-12 Schneider Vfd Atv12hu15m2 - 1.5kw, 2 Hp

- Atv-12 Schneider Vfd Atv12hu22m2 - 2.2kw

- Control Panel

- Programming and Interface Cable

- Proxy Sensor

- Process Control Instruments

- Automation Service

- PLC System

- Panasonic PLC

- SMPS

- MeanWell SMPS Two

- Meanwell SMPS

- LRS-50-24 Meanwell Power Supply SMPS -2

- EDR-120-24 Meanwell SMPS

- LRS-150-24 Meanwell SMPS

- LRS-75-24 Meanwell SMPS

- LRS-100-24 Meanwell SMPS

- LRS-200-24 Meanwell SMPS

- LRS-350-24 Meanwell SMPS

- SE-450-24 Meanwell SMPS

- SE-450-36 Meanwell SMPS

- SE-600-24 Meanwell SMPS

- SE-600-27 Meanwell SMPS

- SE-1000-24 Meanwell SMPS

- SE-1500-24 Meanwell SMPS

- LRS-350-36 Meanwell SMPS

- RS-25-5 Meanwell SMPS

- AC Drive

- Industrial PCS - SCHNEIDER Easy Harmony Panel iPC

- HMI Touch Panel

- Colour Mark Sensor

- Fiber Optic Sensor

- Panasonic Logic Controller

- Servo Driver

- HMI Control Panel

- Schneider Switch Mode Power Supply - SMPS

- Label Gap Sensors

- Baumer Non-transparent Label Gap Sensor

- Di-Soric Optical Label Sensor OGUTI 00550 FG3K-TSSL

- U1HJ001 Fork Transparent Lable Gap Sensor Wenglor

- Telemecanique XUVE04M3KSNM8 non transparent label gap sensor

- Telemecanique transparent label gap sensor XUVU06M3KSNM8

- Baumer OL05.I-GP1B.7WN Non-Transparent Label Gap Sensor

- Mornsun SMPS

- Mornsun SMPS-LM50-22B12 50 Watt 4.2 Amp 12Vdc

- Mornsun SMPS-LM350-10B24 350 Watt 14.6 Amp 24Vdc

- Mornsun SMPS-LM35-22B24 35 Watt 1.5 Amp 24Vdc

- Mornsun SMPS-LM350-10B36 350 Watt 9.7 Amp 36Vdc

- Mornsun SMPS-LM75-22B12 75 Watt 6 Amp 12Vdc

- Mornsun SMPS-LM50-20B12 50 Watt 4.2 Amp 12Vdc

- Mornsun SMPS-LM200-12B12 150 Watt 17 Amp 12Vdc

- Mornsun SMPS-LM75-20B24 75 Watt 3.2 Amp 24Vdc

- Mornsun SMPS-LM75-20B12 75 Watt 6 Amp 12Vdc

- Mornsun SMPS-LM100-20B24 100 Watt 4.5 Amp 24Vdc

- Mornsun SMPS-LM100-20B12 100 Watt 8.5 Amp 12Vdc

- Mornsun SMPS-LM100-22B12 100 Watt 8.5 Amp 12Vdc

- Mornsun SMPS-LM150-20B12 150 Watt 12.5 Amp 12Vdc

- Mornsun SMPS-LM350-12B36 350 Watt 9.7 Amp 36Vdc

- Mornsun SMPS-LM350-10B12 350 Watt 29 Amp 12Vdc

- Mornsun SMPS-LM350-10B48 350 Watt 7.3 Amp 48Vdc

- Mornsun SMPS-LM350-12B24 350 Watt 14.6 Amp 24Vdc

- Mornsun SMPS-LM200-10B24 150 Watt 8.8 Amp 24Vdc

- Mornsun SMPS-LM200-12B24 200 Watt 8.8 Amp 24Vdc

- Mornsun SMPS-LM150-22B12 150 Watt 12.5 Amp 12Vdc

- Mornsun SMPS-LM350-12B12 350 Watt 29 Amp 12Vdc

- Mornsun SMPS-LM100-22B24 100 Watt 4.5 Amp 24Vdc

- Mornsun SMPS-LM200-10B12 150 Watt 17 Amp 12Vdc

- Mornsun SMPS-LM75-22B24 75 Watt 3.2 Amp 24Vdc

- Mornsun SMPS-LM35-20B24 35 Watt 1.5 Amp 24Vdc

- Mornsun SMPS-LM50-22B24 50 Watt 2.2 Amp 24Vdc

- Mornsun SMPS-LM50-20B24 50 Watt 2.2 Amp 24Vdc

- Mornsun SMPS-LM150-20B24 150 Watt 6.5 Amp 24Vdc

- Mornsun SMPS-LM150-22B24 150 Watt 6.5 Amp 24Vdc

- Panasonic Servo

- Schneider VFD AC Drive

- Delta Switch Mode Power Supply - SMPS

- Crompton Ac Drive

- Telemecanique Label Sensor

- Contact Us

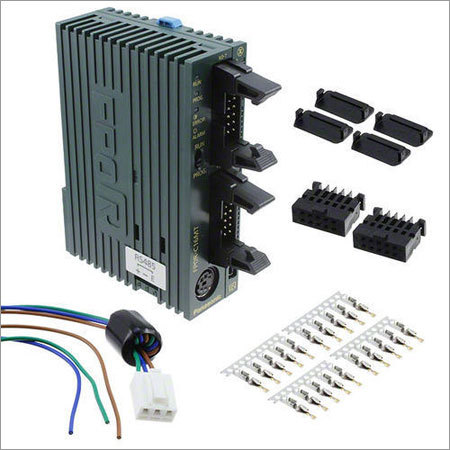

PLC System

100.00 - 1000.00 INR/Unit

Product Details:

- Speed Range High-speed counter up to 100 kHz

- Phase Single / Three Phase

- Load Capacity Up to 500 I/O points

- Remote Control Yes

- Processor Type Microprocessor-based

- Sensor Type Supports digital and analog sensors

- Frequency 50/60 Hz

- Click to View more

X

PLC System Price And Quantity

- 100.00 - 1000.00 INR/Unit

- 1 Unit

- Supports additional I/O and communication modules

- Digital 24V DC, Analog 0-10V/4-20mA

- 10% - 95% non-condensing

- Internal memory and external USB

- 64KB Program memory, 32KB Data memory

- Ladder Logic, Function Block, Structured Text

- <1ms scan time

- Graphical LCD

- MODBUS RTU/TCP, Profibus, Profinet (optional)

- LED status indicators for power, run, fault, and communication

PLC System Product Specifications

- DIN Rail / Panel Mount

- Up to 100 meters for communication interfaces

- Digital / Analog

- Industrial Automation, Process Control, Machine Automation

- Ethernet, RS232, RS485, USB

- Compatible with servo and VFD drives

- 24V DC / 220V AC

- Expandable modules, Real-time clock, Watchdog timer

- IP20

- 0C to 60C operating range

- 50/60 Hz

- Supports digital and analog sensors

- 7 inch TFT (optionally expandable)

- Automatic

- 220V / 24V DC

- Approx. 2 kg

- Single / Three Phase

- High-speed counter up to 100 kHz

- Yes

- Mild Steel enclosure with polycarbonate front panel

- Microprocessor-based

- Up to 500 I/O points

- Supports additional I/O and communication modules

- Digital 24V DC, Analog 0-10V/4-20mA

- 10% - 95% non-condensing

- Internal memory and external USB

- 64KB Program memory, 32KB Data memory

- Ladder Logic, Function Block, Structured Text

- <1ms scan time

- Graphical LCD

- MODBUS RTU/TCP, Profibus, Profinet (optional)

- LED status indicators for power, run, fault, and communication

PLC System Trade Information

- 100 Unit Per Day

- 1 Week

Product Description

Offered PLC System is notable for its compact shape and ergonomic look. Sold under the brand name of Panasonic, this equipment supports cutting edge positioning control, network communication and analog control technology.This PLC System is compatible with Control FPWIN Pro software. Latest features of its software enables user to perform debugging and programming jobs without any difficulty. Long working life, noise free functioning, energy efficient quality, quick installation method and durable housing are some key aspects of this product. Quality of this system has been verified on the basis of its mechanism, operating mode, type of technology it has used and service life.Flexible Integration and Connectivity

The system supports various industrial communication protocolsMODBUS RTU/TCP, Profibus, and optionally Profinetensuring interoperability with existing automation infrastructures. With connectivity options including Ethernet, RS232, RS485, and USB, the PLC allows for seamless data exchange, remote control via HMI/SCADA, and extensive module expansion, making it ideal for both new setups and legacy upgrades.

Robust Design and Expandable Architecture

Encased in a mild steel enclosure with a polycarbonate front panel and rated IP20, the PLC is engineered for durability and longevity in demanding industrial environments. Its modular nature supports additional I/O and communication modules, enhancing system scalability as operational needs grow. LED status indicators provide real-time system feedback for power, run, fault, and communication states.

Advanced Performance and Data Handling

With a microprocessor-based architecture, <1ms scan time, and up to 100 kHz high-speed counting, the PLC is capable of handling sophisticated, real-time control tasks. It features internal data logging with the option for external USB storage, a 32KB data memory, and a 64KB program memory. A built-in real-time clock and watchdog timer further empower precise, reliable automation and monitoring.

FAQs of PLC System:

Q: How does the PLC system support both digital and analog inputs and outputs?

A: This PLC system offers dedicated channels for digital 24V DC as well as analog signals (0-10V/4-20mA), allowing seamless interfacing with a wide range of sensors and actuators in industrial processes.Q: What programming languages are compatible with this PLC for automation projects?

A: Users can program the PLC using Ladder Logic, Function Block, and Structured Text, enabling flexibility in application design and ease of use for engineers with different programming expertise.Q: When is it beneficial to expand the PLCs I/O or communication modules?

A: Expansion is particularly advantageous when increasing production scale or integrating new machines. The PLC supports modular add-ons, making it simple to add extra I/O points or communication capabilities as operational needs evolve.Q: Where is data from the PLC system stored and how is it accessed?

A: Data logging is managed internally and can be stored externally via USB, allowing operators to retrieve, analyze, or back up crucial process and event information efficiently from within the plant environment.Q: What is the process for remotely controlling or monitoring the PLC system?

A: Remote control is enabled through HMI/SCADA systems linked via Ethernet, RS232, or RS485 interfaces. Operators can monitor real-time data, adjust parameters, and diagnose issues from remote or centralized control rooms.Q: How does this PLC system benefit industrial automation applications?

A: Advantages include fast scan times (<1ms), robust environmental tolerance, expandable architecture, and versatile protocol support. These features translate into improved operational efficiency, reduced downtime, and scalability for growing industrial requirements.Q: What safety and environmental standards does the PLC comply with?

A: Built with a mild steel enclosure, polycarbonate front panel, and an IP20 rating, the PLC is designed for industrial environments, offering reliable operation in temperatures from 0C to 60C and humidity levels of 10%95% non-condensing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese